Industrial Analytical Products

View TECO analytical products, along with other trusted brands

TECO provides a comprehensive selection of industrial analytical products designed to optimize performance and reliability in demanding process environments.

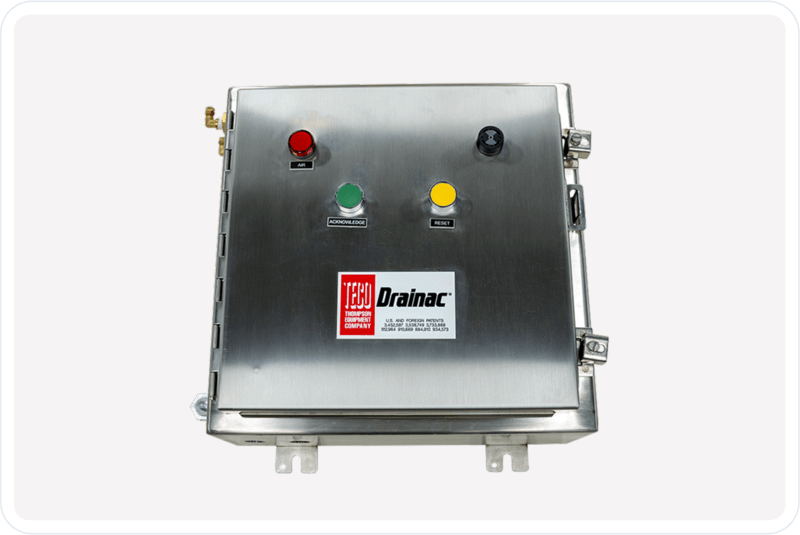

Drainac® Freeness Analyzer

Backed by years of field application in paper mills, TECO’s Drainac® solutions are trusted for improving production stability and yield.

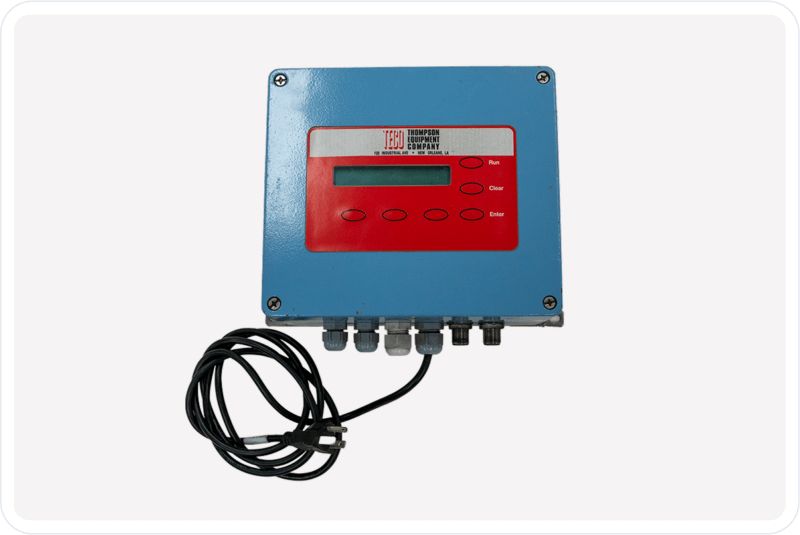

TECO Drainac® Freeness Analyzer

TECO Drainac® Plant Utility Integrity Monitor (PIM)

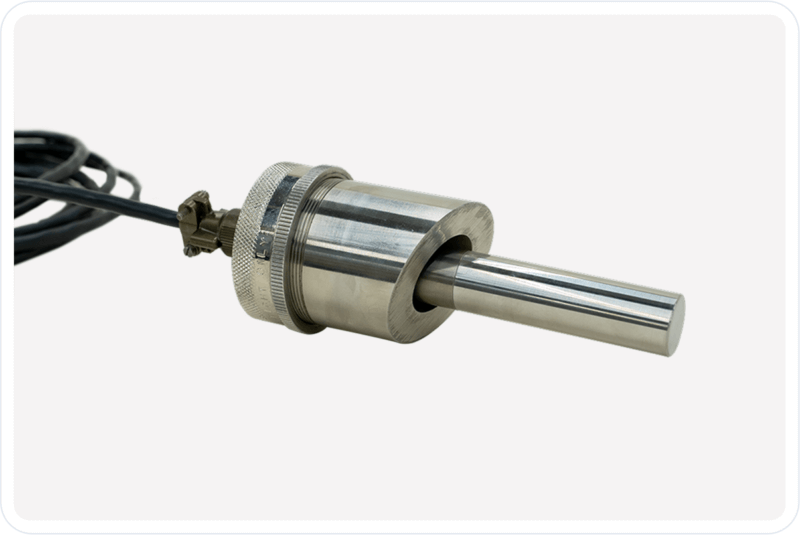

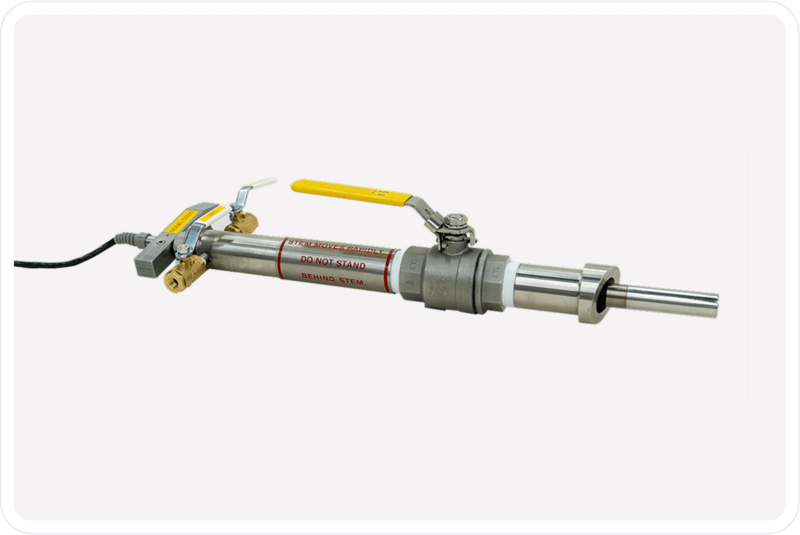

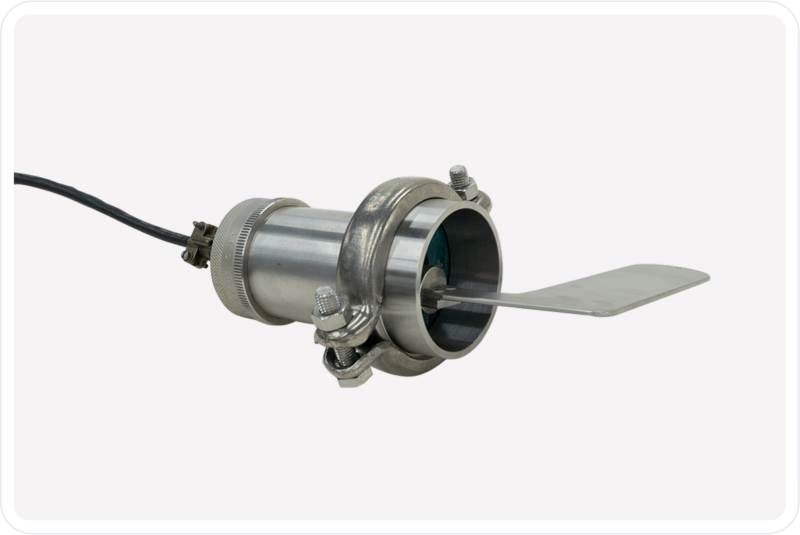

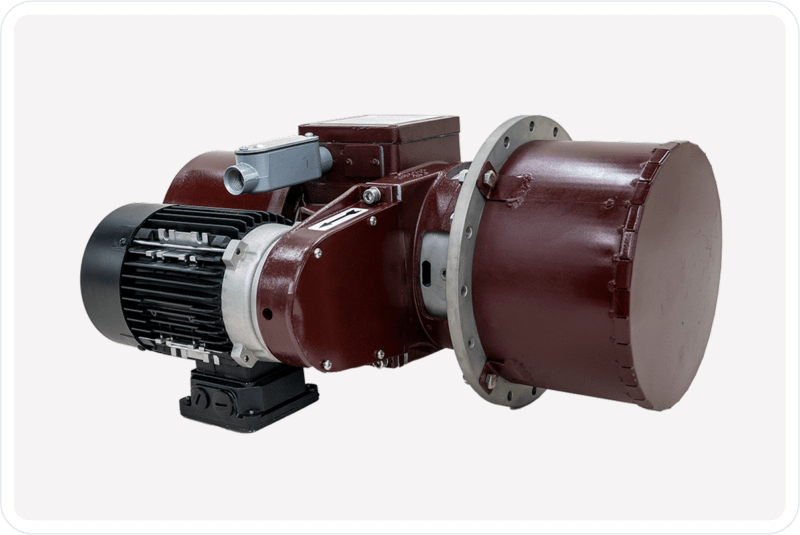

TECO Consistency Measurement Solutions

Built to withstand harsh process conditions, these industrial analytical products provide precise, repeatable readings that improve process visibility, reduce variability, and extend equipment ROI.

TECO TMC-6000 Transmitter

TECO C3000 Fixed Mount Probe

TECO C5000 Retractable Probe

TECO C9700 FixedWing

TECO HK Microwave

TECO MAGIC II

TECO MAGIC III

Get a Quote

Even if you’re not sure which product is best, fill out this form and one of our experts will be in touch ASAP.